Provided by Guangzhou ZijingOrdinary FFUWith reliable quality and complete specifications and sizes, Guangzhou Zijing not only has exquisite technology, but also good after-sales service and high-quality solutions. You are welcome to call us for detailed information on the specific parameters and prices of this ordinary FFU product.

Ordinary FFUGenerally refers to the ordinary FFU fan adaptation unit using AC motors. The FFU produced by Zijing can be as thin as 250. This type of FFU is also called ultra-thin FFU. It is a suspended ceiling unit with an internal fan, used in turbulent and laminar flow clean rooms. It has the characteristics of being able to be connected and used in a modular manner. FFU has concerns such as long working time, low noise, maintenance free, small turbulence, stepless speed regulation, uniform wind speed, and easy installation.

Xitong FFU/Ultra Thin FFU Applicable Fields:

Xitong FFU is widely used in manufacturers of semiconductors, precision electronics, liquid crystal glass, semiconductors, disk drives, as well as in optical and biological industries, for clean production linesclean benchCleanrooms, modular cleanrooms, laminar flow hoods, and other places.

Common FFU product features:

1. Multi gear adjustment

Adopting a multi-stage wind speed design, maintenance free, low vibration, and low noise;

2. Multiple connection controls

Before leaving the factory, each unit is scanned and tested using a dust particle counter in accordance with the standard ISO14644-1 to ensure quality. Thousands of units can be controlled and monitored, reducing the incidence of malfunctions;

3. Low heat generation

High energy efficiency ratio and low heat generation, which can further reduce the heat generation in the additional working environment area;

4. The high wind speed and series connection of ordinary DC fan filter unit (DC FFU) are ceiling mounted units with internal fans, used in turbulent and laminar flow clean rooms. They have the characteristics of modular connection and can be used with an average wind speed of 0.45m/s ± 20% on the outlet surface.

Ordinary FFU generally refers to FFU fan filtration units that use AC motors, The thinnest FFU thickness can reach up to 250mm. This type of FFU is also known as ultra-thin FFU. It is a hanging unit with an internal fan, used in turbulent and laminar clean rooms. It has the characteristics of modular connection and use. FFU has the advantages of long working time, low noise, maintenance free, low vibration, stepless speed regulation, uniform wind speed, and easy installation.

Common FFU application areas: widely used in semiconductors, electronics, flat panel displays, optics, cleanrooms, etc.

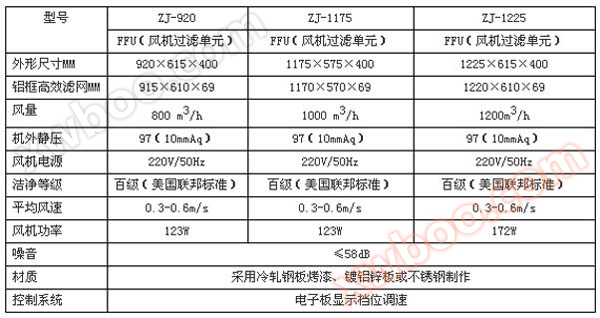

Common FFU specifications, dimensions, and technical parameters:

The air purification products and equipment provided by Guangzhou Zijing include air shower rooms, cargo shower room,Primary Filter,medium efficiency filter,High efficiency filterUltra clean workbench, clean workbench, transfer window, air shower accessories, air shower controller, chemical filter, FFU fan filtration unit, air purifier, clean room, fresh air cabinet, filter cabinet, fume hood, washbasin, clean sampling vehicle, high-efficiency air outlet and other cleanroom and supporting purification products. Cleanroom purification equipment is widely used in electronics, semiconductors, biopharmaceuticals, food processing, nuclear industry, automotive manufacturing, air conditioning and heating industries and fields.

Zijing specializes in purification equipment and purification engineeringCleanroom contractor, cleanroom engineering, cleanroom construction, cleanroom cleanliness testing, cleanroom solutions, cleanroom standards, cleanroom construction, cleanroom equipment, cleanroom design, cleanroom construction, cleanroom maintenance. Cleanroom is also known as purification workshop or cleanroom cleanroom.

Requirements for after-sales service time of purification equipment:

Whether it is paid after-sales service or free after-sales service, customers provide feedback on equipment after-sales issues to Zijing. After our company provides a solution and the customer confirms the solution:

1. Arrive at the site within 24 hours within the Pearl River Delta and Yangtze River Delta to solve after-sales service problems;

2. In other areas, it is generally within 48 hours to arrive on-site to solve after-sales service problems, while in special remote areas, it is up to 96 hours to arrive on-site to solve after-sales service problems.

Requirements for after-sales service time of purification equipment:

Whether it is paid after-sales service or free after-sales service, customers provide feedback on equipment after-sales issues to Zijing. After our company provides a solution and the customer confirms the solution:

1. Arrive at the site within 24 hours within the Pearl River Delta and Yangtze River Delta to solve after-sales service problems;

2. In other areas, it is generally within 48 hours to arrive on-site to solve after-sales service problems, while in special remote areas, it is up to 96 hours to arrive on-site to solve after-sales service problems.

Original source: Guangzhou Zijing http://www.zj-filter.com/ Li Gong (139-2875-8616)